Get the SMT machine fits you best

You have come to the right place if you're looking forward to setting up your own SMT line. Seamark SMT is proud to offer you the PCB assembly equipment from small-scale to large-scale SMT production.

Our Service

Complete SMT Solution

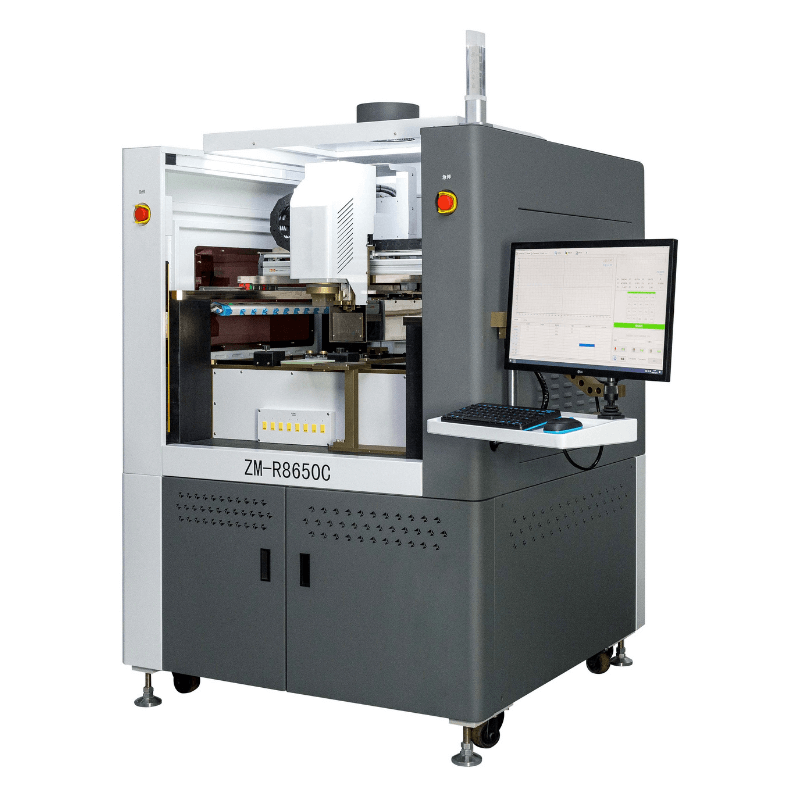

Our turnkey SMT solution combines flexible and reliable PCB assembly equipment into one complete solution.

SMT Equipment Consulting

We can provide SMT machines that fit you best, including pick and place machines, stencil printers, soldering machines, etc.

Unlimited Lifetime Support

We're proud to provide unlimited lifetime support, installation, training, and after-sale service for all of our machines.

Why Choose Us

We have been in the SMT industry for more than 10 years, work with a strong network of SMT equipment and parts suppliers. So we distribute high-quality SMT machines globally and help our customers build their SMT line profitable.

Our Customer